Jan 10,2024

Throughout the Whole Process of Project Delivery, Damon Serves Customers with High Quality

Quality, as one of the three core elements of project management, its management results directly determine the project delivery and customer experience. Therefore, customers usually pay attention to the internal quality assurance mechanism and the strategic policy of continuous quality improvement. In the project implementation stage, after the quality problem occurs on the project site, the customer is concerned about the speed and response aging of quality problem, as well as the issuance of measures to avoid the recurrence of similar quality problems. At the same time, because their own business characteristics and project scenarios are different, they also focus on the implementation of specific metrics and parameters in customized solutions and services. Therefore, project quality management is a key factor in ensuring that projects can be delivered smoothly and make customer satisfied.

Different from the quality management of products and factories, the quality management of projects pays more attention to the inspection and control of project process compliance, rather than the quality control of equipment system itself. In recent years, Damon attaches great importance to the quality management of projects, and effectively improves the quality management level of the whole life cycle of projects by building a project quality management system centered on customer satisfaction, enabling the quality strategy and strategy of system integration business, and helping enterprises to improve core competitiveness.

From program planning, engineering technology to software development, and then to project management and after-sales service, Damon will implement the quality level control of the whole link, such as the technical agreement, planning scheme, and review of non-standard applications in the early engineering and technology stage, strictly requires the self-inspection of each link, as well as the secondary confirmation of the previous link’s output by the work receiver, for the customized quality needs of customers, the relevant departments of project management and program planning will translate this information into Damon standardized information and pass it to the downstream links.

Through customized project quality control plan, Damon manages the control elements of project quality in a closed loop, collects, disassembles and analyzes the quality data of project in a fixed cycle, and regularly informs the relevant departments of the quality improvement items that need to be focused on to help better avoid and continuously improve the quality problems that may occur in the whole process of project.

In order to fully guarantee the smooth delivery of customer projects, Damon checks the compliance of quality operations and process delays of the whole business chain by combining system and business, sorts out the quality control points of the major execution links of project, and plans the project site quality control plan that is more suitable for Damon 's business type, assists related departments to identify and improve missing quality control actions throughout the project process.

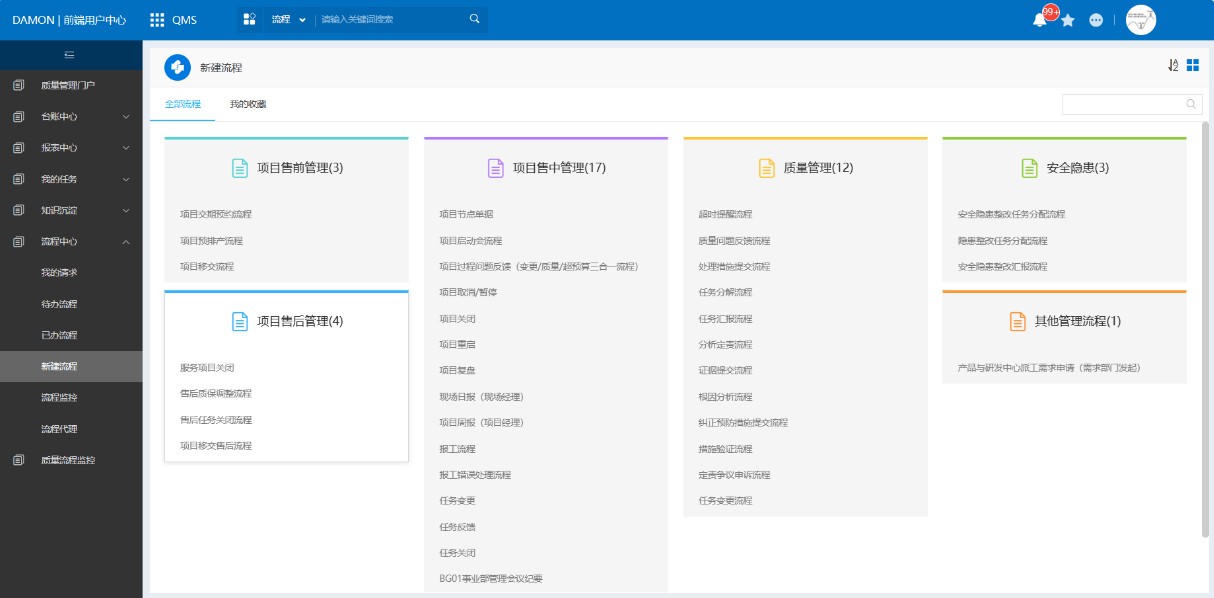

At the same time, Damon also introduces and optimizes the QMS quality management system as a powerful tool for cross-link quality management, from the identification of quality problems, responsibility attribution, initiation, analysis, correction and to issuance of preventive measures, to define and standardize the standards of quality operations.

As one of the main information input sources of QMS system, PMS project management system also refers to the overall idea and architecture of QMS. Through the organic combination of the two, Damon can transmit important information such as the impact of quality problems, the demands for solving quality problems and the possible losses caused by quality problems to all stakeholders, and through the way of approval at the level, so that relevant business departments can obtain the necessary information elements. The QMS system with feedback function can complete the closed-loop management of the quality problems collected by PMS, and realize the comprehensive information management of Damon quality business.

Damon has always insisted on quality every day, every month, everyone, manages the quality throughout the whole business process. In the future, Damon will continue to take quality as the core vitality of the enterprise, strengthen the output of high-quality work in the project implementation end, make full use of digital management tools, constantly improve the project quality management ability, perfect delivery of intelligent logistics system solutions that satisfy customers, and create value for more industry head customers!

Share to: