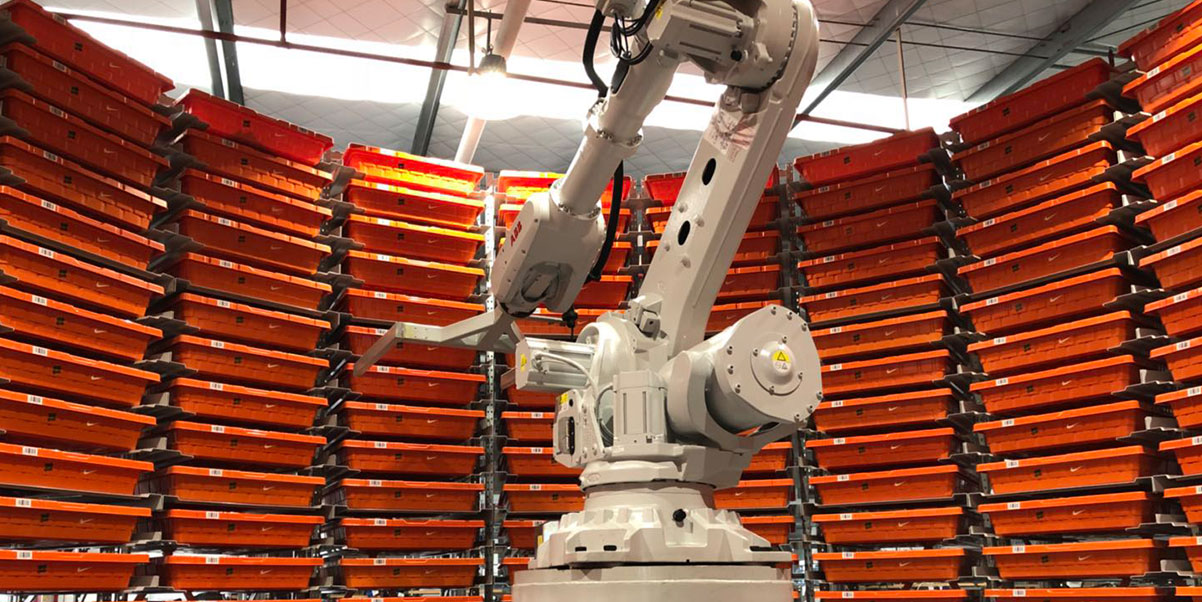

Robot Mini-Load

An integrated solution for temporary storage, ranking, sowing, and picking.

The Robot Mini-LoadTM system refers to a set of standardized and modular small work bin-style and automated stereoscopic warehouses. It has unparalleled flexible scalability, and advantages such as unmanned operation, high efficiency, strong flexibility, easy maintenance, low construction costs, and short delivery periods. It is particularly suitable for work bin processing in the processes such as caching, ranking, picking and sowing, and unmanned picking for internal logistics of the manufacturing industries and e-commerce logistics centers. The Robot Mini-LoadTM system is composed of standardized multi-joint robots, circular multi-layer storage racks, location and safety sensors, WCS, and an intelligent high-precision localization system, etc. It can work together with the i-G5 Box Roller Conveyor System to form an automated, standardized, and unitized intelligent storage system. The system is also a standard intelligent unit in an intelligent logistics system. Working together with WMS and PHEGDA (PHM) system, it can realize big data analysis and provide suggestions for making decisions on system equipment maintenance.

Features

Cost-effective and Efficient

It supports the high-speed operation of 380 box-times of circulation/ hour/standard group, and its operation of multiple groups in parallel can multiply the throughput.

Robots operate around the clock (24/7) to guarantee continuous and efficient storage and pick-up.

The whole process is unmanned, which saves costs and avoids problems such as labor shortages and personnel management difficulties.Fast Deployment

With standardized manufacturing and assembly, it achieves the comprehensive delivery cycle of only 50% of that of traditional systems.

The standardized and modular design supports fast assembly/disassembly and easy maintenance.

The standardized modules support a combination of any multiple modules in parallel and support easy deployment.High Availability

One machine offers multiple functions for purposes such as caching, ranking, sorting and sowing, and unmanned sorting.

Its standardized three-dimensional caching saves space and brings convenient system expansion.

With a wide range of applications, it is suitable for various scenarios such as protective storage of high-value commodities, automatic material supply, and execution of shipment orders.

-

Cost-effective and efficient

Cost-effective and efficient -

High availability

High availability -

Fast deployment

Fast deployment -

Extensive application

Extensive application

Model

Robot Mini-load TM Intelligent Logistics System

Robot Mini-load TM Intelligent Logistics System

Robot Mini-load TM Intelligent Logistics System

Robot Mini-load TM Intelligent Logistics System

How Can We Help?

If you do have any question about our products and solutions, we are happy to communicate with you.

Contact us

Service Support

We provide you with the better advice and quick actions any time after purchasing our products.

Get help

By clicking on the button “I accept” or by further usage of this website you express consent with usage of cookies as well as you grant us the permission to collect and process personal data about your activity on this website.Such information are used to determine personalised content and display of the relevant advertisement on social networks and other websites. More information about personal data processing can be found on this link.Read More