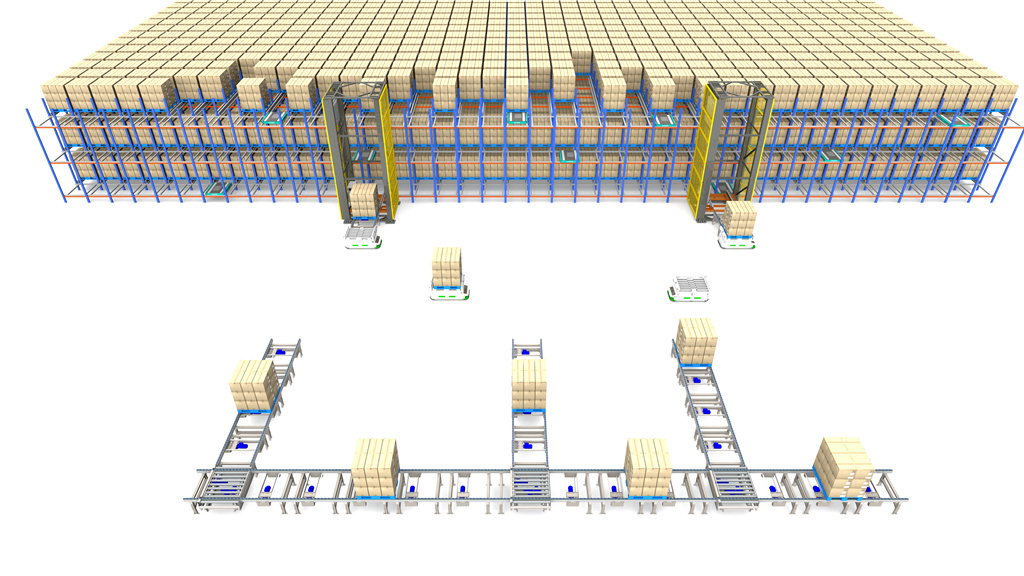

AGV for Conveyor Connection

An automated connection and handling solution for pallet and box roller conveyor systems

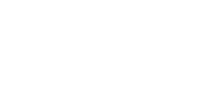

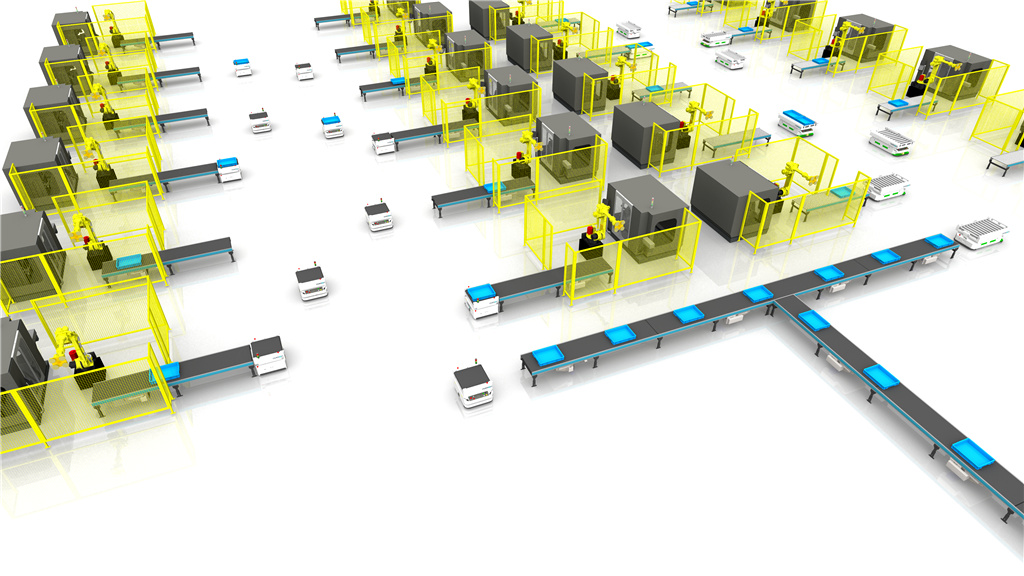

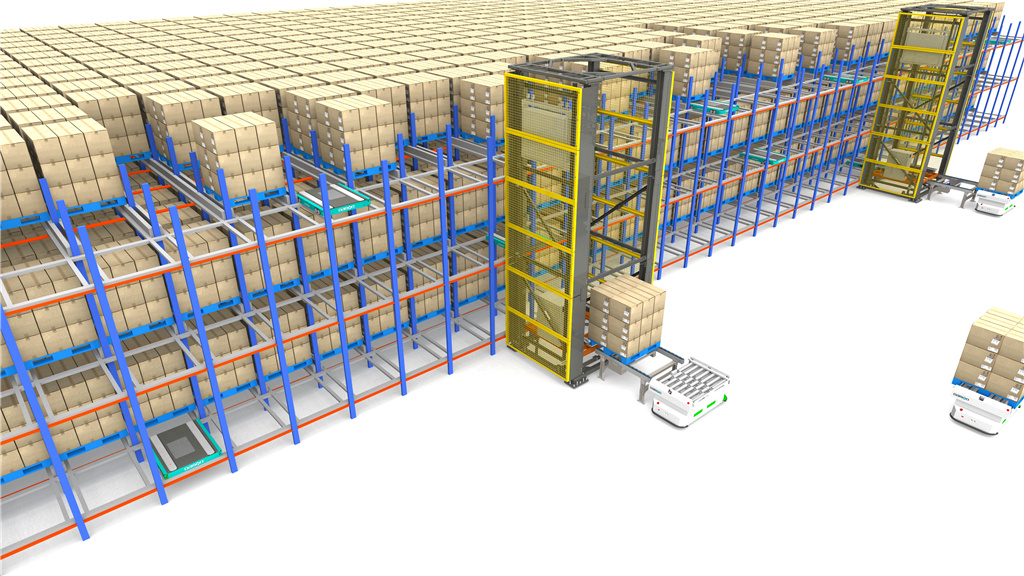

Relying on its own conveying line, an AGV for conveyor connection can guide pallets or boxes on the connected conveying line to itself and transfer the pallets or boxes to the target conveying line, or specify a location for other automated equipment to complete the handling relay. AGVs for connection are divided into AGVs for box connection and AGVs for pallet connection. AGVs for box connection are suitable for transferring boxes, and AGVs for pallet connection are suitable for transferring H-shaped, three-vertical-line shaped, square window shaped and two-sided pallets. AGVs for conveyor connection can be combined with automatic charging piles, localization systems, task systems, navigation systems, and others to form an AGV system for conveyor connection and handling. The system reserves standard software interfaces for quick connection to WCS, WMS, MES, ERP, OMS, and other external systems to realize continuous unmanned intelligent handling operations. It is a "handling expert" on material supply, putting finished goods in storage, and cross-docking transfer.

Features

Extensively Compatible

The AGV itself is equipped with conveying lines to easily connect to the conveying system.

It offers multiple types of lines to support the handling of a variety of boxes and pallets.

Seamlessly connect to MES, ERP, and OMS to perform handling tasks efficiently and accurately.Highly Available

It Operates around the clock throughout the year (7×24h×365) regardless of the environmental temperature.

Simple, sturdy with a durable structure, and an extremely low comprehensive cost.

Cooperate with freight elevators to realize automatic handling across floors.Flexible and Convenient

A single AGV can be ready for operation when imported into the system, and multiple AGVs can be deployed in 1 to 2 weeks.

The number of AGVs can be increased or decreased along with changes in business development, and the AGVs can be immediately added to the system for operation.

It supports customization of process combination and charging strategy to respond to internal management optimization.

-

Modular application

Modular application -

Flexible expansion

Flexible expansion -

Stable and reliable

Stable and reliable -

Efficient and flexible

Efficient and flexible

Model

DC-50B

DC-50R

DC-1200R

How Can We Help?

If you do have any question about our products and solutions, we are happy to communicate with you.

Contact us

Service Support

We provide you with the better advice and quick actions any time after purchasing our products.

Get help

By clicking on the button “I accept” or by further usage of this website you express consent with usage of cookies as well as you grant us the permission to collect and process personal data about your activity on this website.Such information are used to determine personalised content and display of the relevant advertisement on social networks and other websites. More information about personal data processing can be found on this link.Read More