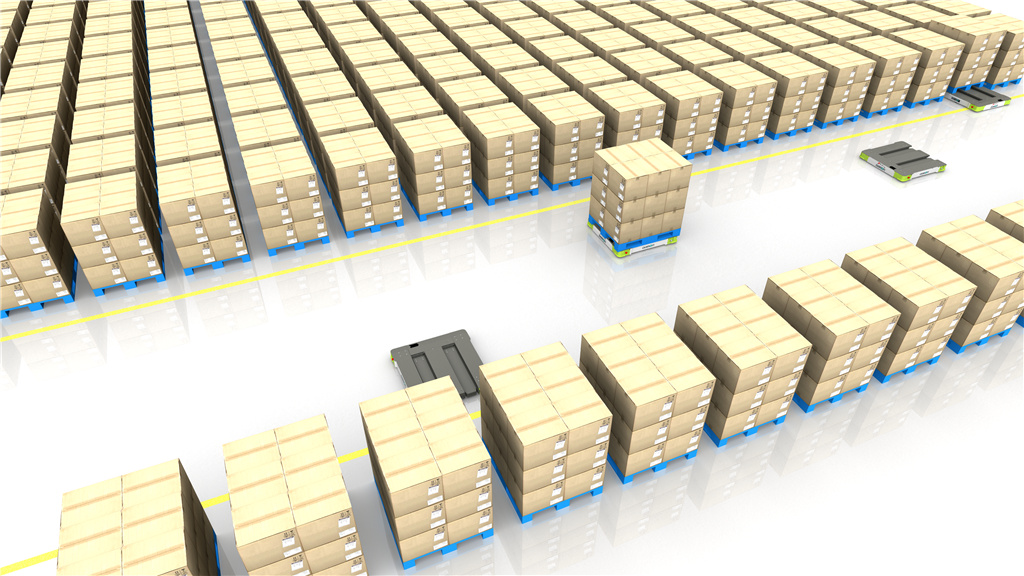

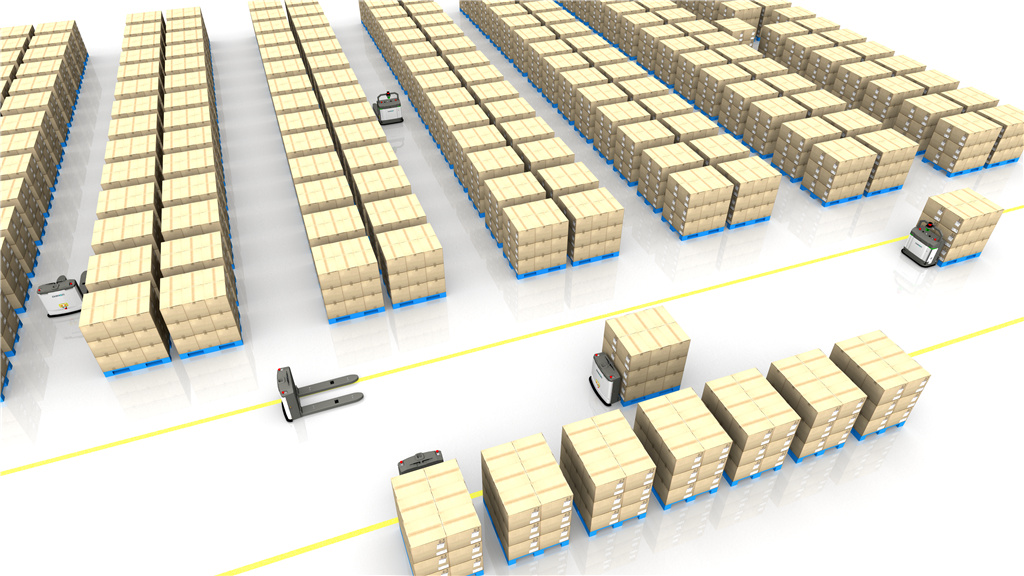

Pallet-handling AGV

An unmanned solution for handling pallets on the ground level

Pallet-handling forklift AGVs are a kind of AGVs for handling that are very commonly used in the intelligent handling system. Such forklift AGVs are not able to lift items to a high level, and are suitable for moving and handling one-sided pallet items, such as H-shaped, three-vertical-line shaped and nine-legged items, on the ground level. With no need to make any modifications to the on-site environment, the AGVs can be used for short-distance, medium-distance and long-distance turnover and handling at the scene, making them almost suitable for handling operations at factories, warehouses and logistics centers of all industries. Pallet-handling forklift AGVs can be combined with automatic charging piles, localization systems, task systems, navigation systems, and others to form an intelligent AGV handling system. The system reserves standard software interfaces for quick connection to WCS, WMS, MES, ERP, OMS, and other external systems to realize unmanned intelligent handling operations.

Features

Excellent Visual Navigation

Using the unique intelligent "new visual" sensing technology, it achieves reliable and stable navigation regardless of strong light and darkness.

Without reflectors, it neither changes the on-site environment nor is affected by changes in the on-site environment.

AI image processing and real-time auto body control are organically integrated to achieve real-time path optimization and accurate localization.Convenient, Flexible, and Easy to Use

A single AGV can be ready for operation when imported into the system, and multiple AGVs can be deployed in 2 to 3 weeks.

The number of AGVs can be increased or decreased along with changes in business development, and the AGVs can be immediately added to the system for operation.

It supports customization of process combination and charging strategy, and its interface is user-friendly and easy to operate.Significantly Improve Efficiency

Reduce labor by 60%-80% to improve efficiency and weaken the effects of labor shortage and annoying management issues.

Reduce labor intensity and lower error rate to improve client experience.

AGVs' operation efficiency and accuracy rate are always stable and consistent.Highly Available

Suitable for handling operations on the ground level in almost all scenarios.

Cooperate with freight elevators to support unmanned transportation across floors.

Operate around the clock throughout the year(24/7/365) regardless of the environmental temperature.

-

Visual navigation

Visual navigation -

Intelligent algorithm

Intelligent algorithm -

Stable and durable

Stable and durable -

Efficient and flexible

Efficient and flexible

Model

DF-C2500 V

DF-C2500 L

MiNi-H

MiNi-S

MiNi Pro

MiNi Pro

How Can We Help?

If you do have any question about our products and solutions, we are happy to communicate with you.

Contact us

Service Support

We provide you with the better advice and quick actions any time after purchasing our products.

Get help

By clicking on the button “I accept” or by further usage of this website you express consent with usage of cookies as well as you grant us the permission to collect and process personal data about your activity on this website.Such information are used to determine personalised content and display of the relevant advertisement on social networks and other websites. More information about personal data processing can be found on this link.Read More