Jun 12,2023

Damon strives to create an efficient and smart logistics network for this fashion giant

An e-commerce logistics center intelligent conveying and sorting system project of a fashion industry group

Industry:Fashion

Location:Huiyang, Guangdong, China

Area:80,000 m2

【Background】

A fashion industry group has over 10 fashion brands, 60+self-owned warehouses, and about 20,000 self-operated stores, making it the key retail distributor in China for multiple well-known sports brands worldwide. To meet the growing demand for orders, the group has established a logistics subsidiary and a large e-commerce logistics center in South China.

【Challenges】

The e-commerce logistics center has many orders to process, which are mainly handled and operated manually. Therefore, large amount of space is required for picking. The picking error rate is high and the sorting efficiency is low, with low level of informatization and digitization in logistics management. The multi-dimensional supply chain logistics efficiency is unable to respond in a timely manner during peak and promotional seasons.

【Solutions】

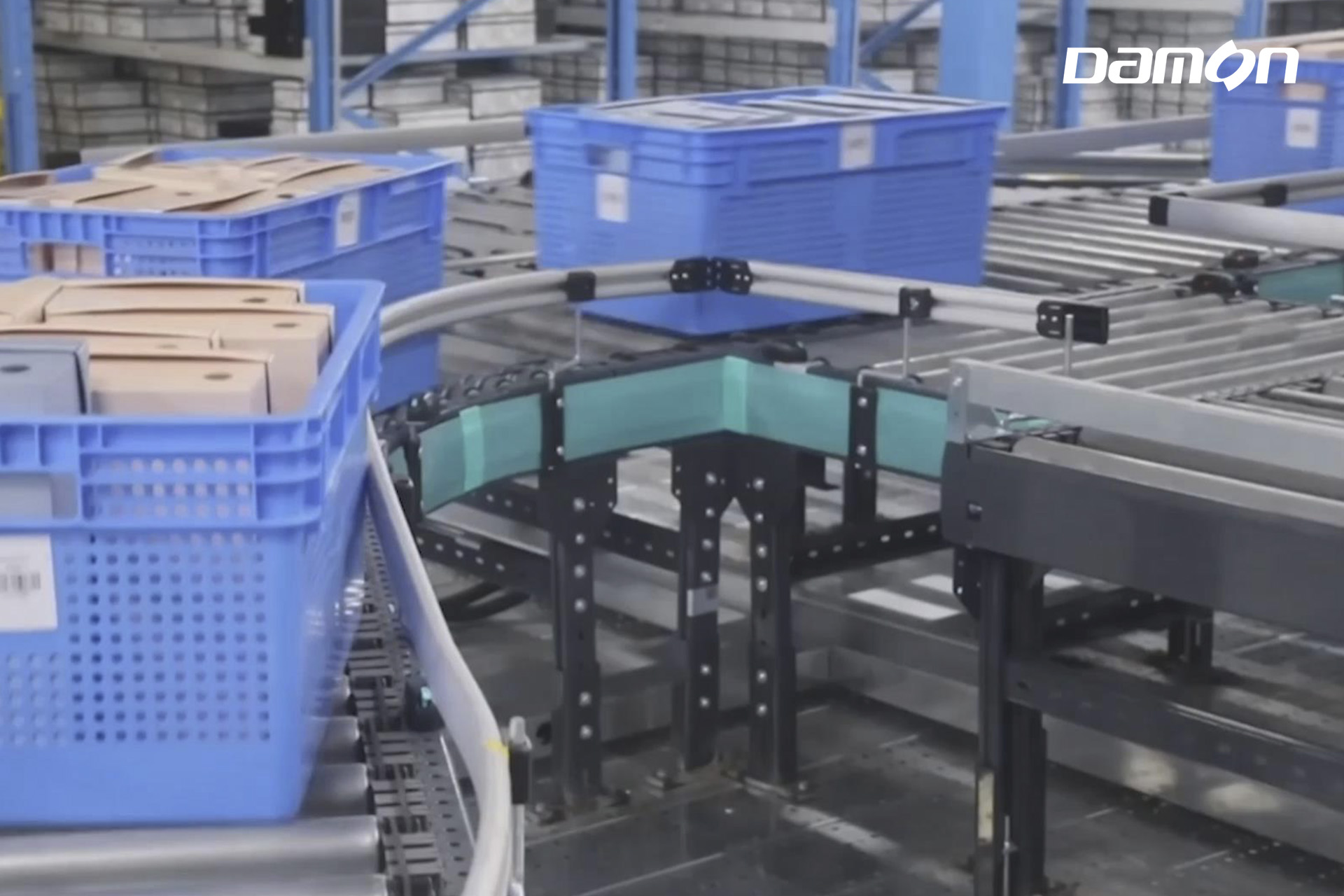

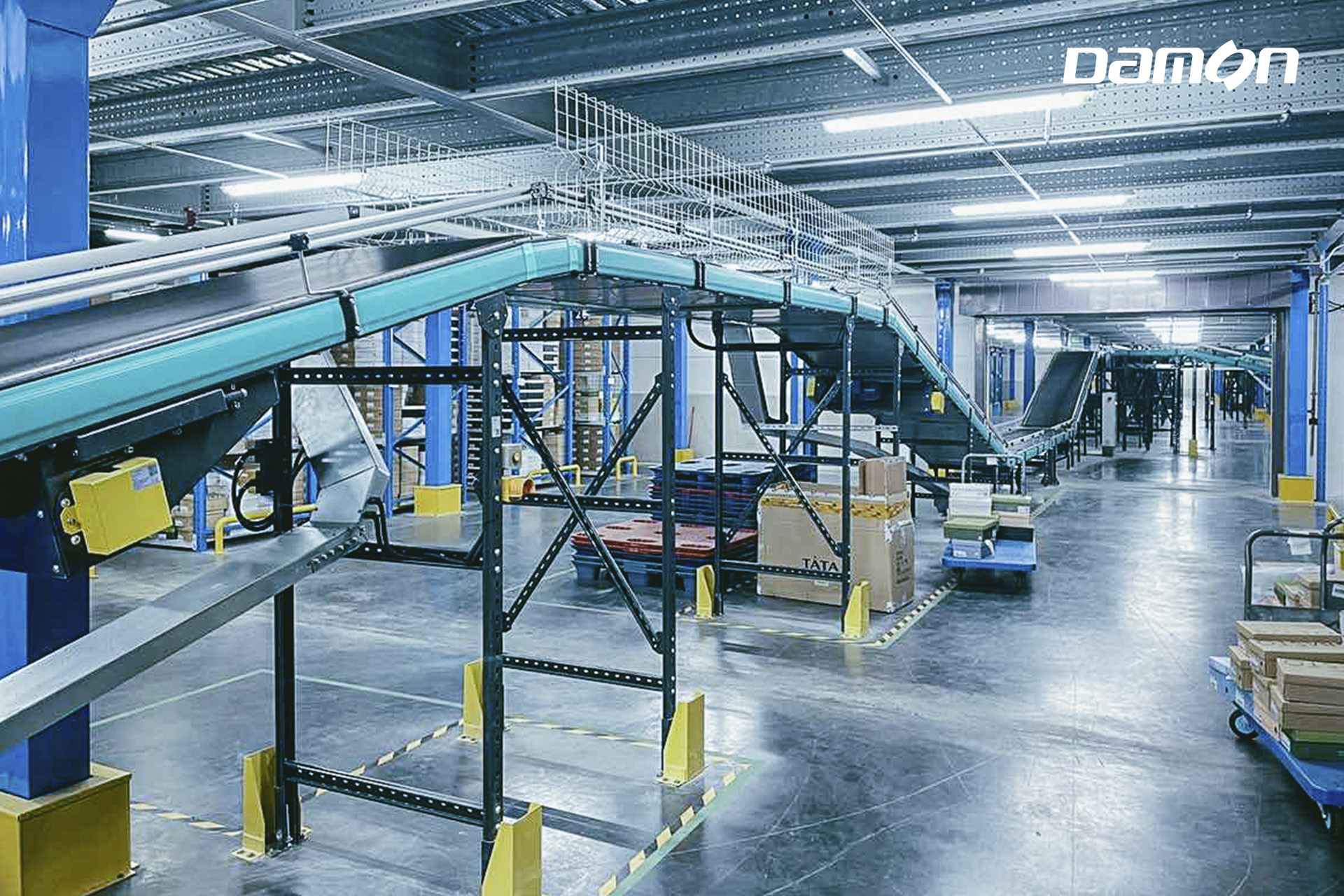

A 3km i-G5 conveyor line has been designed for this e-commerce logistics center. It can achieve different functions such as goods receiving, picking and delivery, and empty containers backflow, With the up and down design, it connects floors and circulates containers in the whole warehouse. It improves the efficiency of automatic receiving and delivery for customers.

In the picking area, the double-sided DPS seeding walls with adjustable waiting stations make the manual picking comfortable. The roll-to-roll delivery conducted by small grids improves the picking efficiency and accuracy.

In the picking area, the double-sided DPS seeding walls with adjustable waiting stations make the manual picking comfortable. The roll-to-roll delivery conducted by small grids improves the picking efficiency and accuracy.

Damon reasonably plans the priority of the merging lines in the packing area. And the confluence rate is improved by two in one conveying with high density at a low-speed. The intelligent sensing system based on IoT is combined with independently-developed logistics management software to monitor the confluence flow and equipment status in real-time, making goods conveying smoother.

shoe boxes deliver precisely at a high speed. In addition, dynamic weighing devices are added to automatically scan and double check the goods, which is convenient for customers to settle with the parcel express companies.

【Application Effects】

The logistics center has achieved significant results since it was officially put into operation. 1)The receiving capacity of the system is 2,400 pcs/h, with the confluence capacity of 2,800 pcs/h for each conveying line.

2)Its outbound sorting efficiency reaches 5,000 orders/hour, and the total delivery efficiency is up to 9,000 orders/hour.

3)During the promotion period, the order processing peak reaches 150,000 orders, which can support the business growth in the future.

Share to: