Sep 06,2021

Picked Troops and Sharp Weapon! See how the Damon i-G5 Platform Plays a Great Role in the Intelligent Logistics System of All Walks of Life?

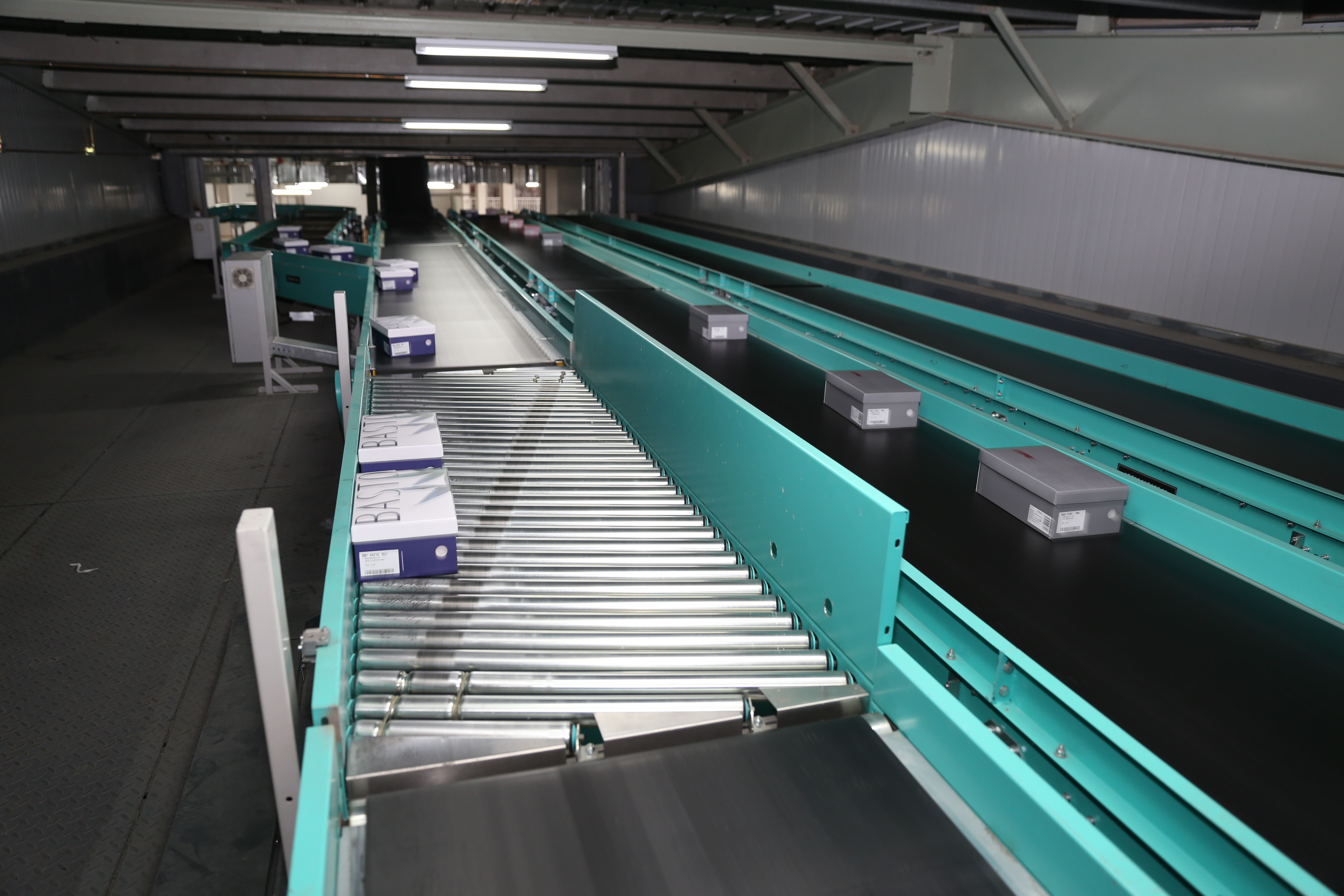

Carton type conveying system - enabling major logistics links

COVID-19 has promoted online shopping to become the mainstream consumer trend. In 2020, Double Eleven logistics orders broke 2 billion 250 million orders. At the same time, the timeliness of e-commerce logistics distribution is moving forward to the "minute level", which makes the market put forward higher requirements for the operation efficiency of conveying and sorting equipment. In addition, 5G technology has entered the application stage, which further promotes the rapid innovation of intelligent conveying and sorting technology.

The efficient automatic transportation and sorting system can be widely used in e-commerce, supermarket retail, shoes and clothing textile, medicine, intelligent manufacturing and other major industries. It undertakes multiple key processes such as broken case picking, transportation and handling, path sorting and has become one of the core links of the logistics warehouse distribution center. In particular, the broken case picking link has high requirements for the conveyor, it must have powerful functions such as high-speed horizontal lateral transfer, zero pressure connection and release in the whole process, etc. With such a high standard of equipment performance, ordinary carton conveyor is difficult to achieve, while Damon's i-G5 Modular Intelligent conveying platform can be easily competent.

"Intelligent, Convenient, Green, Beautiful", create a high-performance carton type conveyor platform

Damon i-G5 products have a brand-new logistics digital platform, equipped with intelligent chips for automatic sensing, combined with Phegda system (PHM) to provide various intelligent services, and realize predictive maintenance of equipment through data acquisition, so as to keep the system in the best state all the time. The speed of i-G5 conveyor can reach 120m / min at most. Intelligent drive, EZQube intelligent controller / DSmart intelligent starter ensure the efficient operation of the platform. Compared with the previous generation of products, the installation and commissioning efficiency has been improved by 38%, the project delivery time has been nearly doubled, the operation and maintenance time has been saved by 50%, and the troubleshooting time has been saved by 80%. In addition, i-G5 adopts low-noise mechanical structure design, and the noise of conveyor is 6 dB lower than that of the previous generation; Equipped with energy-saving AC power roller / AC micro motor, the energy consumption is reduced by 25%, which is in line with the environmental protection concept of sustainable logistics development.

Standardized modules, change flexibly with diverse customer needs

The flexibility of i-G5 intelligent conveying platform is mainly reflected in standardized production equipment and modular construction system. "Standardization" means that the module embedded interface and development benchmark are unified, which is not only to plan the system for specific projects, but also to design products for accurate market demand; "Modularization" makes the parts between different equipment interchangeable and various models can be combined with each other, which is conducive to adjusting the system layout according to customer needs, so as to shorten the delivery cycle, reduce the installation cost, make the later maintenance and expansion easier, and improve customer’s degree of satisfaction.

Feel just like a duck to water in major industries , the typical application of Damon i-G5 is revealed

Through the combination of Damon i-G5 complete set of conveying models with other series of products and functional modules, according to different business needs, it can be deployed in various logistics conveying scenarios, so as to form distinctive system solutions and realize the conveying function of maximum efficiency.

E-commerce industry

Damon provides a large volume of carton conveying equipment for the logistics bases of Suning and Cainiao. The huge conveying and sorting system combined with cross belt sorter has a maximum conveying capacity of 20000 pieces / hour, which greatly improves the distribution efficiency of e-commerce logistics center. In Vipshop project, the same system is configured, and its maximum conveying efficiency is 4000 cartons / hour.

In view of the huge, multi-variety , small batch and high frequency characteristics of e-commerce SKUs, the i-G5 platform can also be seamlessly connected with the carton type multi-shuttle system, equipped with the "Cargo-to-person" picking workstation, carry out the overall system layout, and build a new centralized "multi-shuttle cargo-to-person" picking system solution integrating "access, transportation and picking", which greatly improves the efficiency, and ensure efficient performance of orders. Realize the functions of warehousing, picking, inventory and replenishment of goods of different specifications, among them, it is very important to design sufficient buffer capacity of carton conveyor line to match the ex-warehouse capacity of multi-shuttle aisles and the picking capacity of operators.

Fashion industry

Damon i-G5 conveying line can realize the adjustment of conveying goods gap and merging wave queue, so as to better control the wave of merging window, and help Belle logistics center complete the loading, replenishment and sorting out transportation of tens of thousands of carton type SKUs with different sizes of shoes, clothing and accessories. After merging, the comprehensive transportation capacity of the conveyor line is increased to 3000 cartons / hour.

I-G5 can also be docked with automatic sorting equipment such as cross belt sorter, sliding shoe sorter, Eurosort sorter and intelligent fast storage and storage system, so as to help industry giants such as Cabbeen, Samsonite, La Chapelle, Day Broadcast and Peacebird improve the fluency between storage and distribution, make the comprehensive transportation capacity of the system 1500-1800 boxes / hour, and save a lot of manual handling, and effectively improve operation efficiency.

Supermarket retail industry

In recent years, the logistics demand of new retail formats has shown explosive growth. Taking HEMA fresh as an example, Damon has built a set of high-speed i-G5 intelligent carton conveying system for its distribution warehouse, with a maximum conveying efficiency of 2200 cartons / hour. The application prospect of conveying and sorting system in the circulation of fresh food is broad.

In addition, Damon has planned i-G5 conveyor lines for domestic supermarket benchmark brands such as Liqun group, Northland Mall and Yonghui Supermarket, which are cleverly matched with various sorting modules and systems to help complete the multi scene distribution task of massive commodity SKUs with different shapes and weights. Among them, the comprehensive transportation capacity of Northland Mall project can reach 6000 cartons / hour, and the accuracy rate is as high as 99%, which provides a reliable guarantee for customers to realize the service commitment of "Delivery In One Hour Within Three Kilometers ".

Pharmaceutical industry

In the pharmaceutical field, i-G5 conveying platform can be docked with sorting equipment such as power roller transfer and narrow belt sorter, realize the dynamic gap adjustment of sorter, support the transportation of carton pharmaceutical raw and auxiliary materials and finished products, as well as 90 ° transfer, parallel transfer, two-way transfer and double station transfer. In Yongsheng Pharmaceutical, Guangzhou Pharmaceutical and Hongxiang Yixintang projects, the maximum conveying flow of the system is 2800-3000 cartons/hour. While improving the circulation efficiency, the error rate of conveying and transferring is very low. In addition, the carton type conveying line can be combined with vertical lifter and high-speed reciprocating lifter to form a cross-floor solution.

Intelligent manufacturing industry

In order to realize the transformation of production and management mode in the field of intelligent manufacturing, the handling of materials and finished products in the workshop also depends on the intelligent conveying system. For example, in the intelligent factory project of Huawei and Dahua, Damon planned the i-G5 carton conveying system for it, which connects all production processes in the workshop, runs through all the operation processes of material warehousing and production supply in the whole factory, effectively improves the production and logistics efficiency, and the maximum conveying capacity of the system can reach 3000 cartons / hour.

As a leading provider of intelligent logistics system and core equipment in China, Damon is committed to providing customers with increasingly diversified intelligent transportation system solutions to meet the business needs of logistics links such as material procurement and warehousing, production warehousing, production picking and finished product delivery in different industries. Through the standardization, modularization and intelligence of i-G5 products, help more industry leaders achieve gain and create value.

Share to: