Aug 09,2021

Damon high-speed multi-shuttle system: let space and efficiency create value for clothing warehousing

Intelligent logistics technology VS clothing fashion change

With the accelerated pace of digital transformation of garment industry, garment enterprises pay more and more attention to the application of automatic logistics equipment technology, and increase the investment in the construction of automatic garment logistics center, so as to improve logistics efficiency and reduce dependence on manpower. However, the overall supply of China's garment market exceeds demand, there are a wide range of garment categories, fast new styles, large fluctuations in delivery volume, short fashion cycle, strong seasonality, it is difficult to estimate the return volume, stores have high requirements for replenishment efficiency, a large number of supply chain problems such as overstocking of out of season products, cross season management of new products, processing of multiple models of the same product, etc, but it further increases the difficulty of warehousing operation and management in the garment industry.

The development and consumption upgrading of mobile Internet have triggered changes in clothing supply chain and logistics. The garment industry has become one of the active industries in the new online and offline multi-channel business models such as stores, online shopping, E-commerce and live broadcasting. Personalized consumer demand, diversified consumption scenarios and diversified order types have derived a variety of differentiated garment logistics services, and have high timeliness requirements for operation modes such as storage, picking and review.

The fragmentation of clothing store orders and the rapid growth of E-Commerce orders pose a great challenge to the rapid response of logistics, which requires the coordinated development of upstream and downstream of the supply chain and the visualization of the whole process of logistics. In order to realize multi-warehouse linkage, fast in and fast out, warehouse location release, efficient automatic logistics system is born to meet the needs of goods storage, transportation and distribution. At the same time, the logistics technology demand of garment supply chain has changed, intelligent storage system has become the focus, and omni-channel, intelligence and flexibility will become the development direction of garment logistics in the future.

Flexible innovation, superior intelligent carton "three-dimensional library"

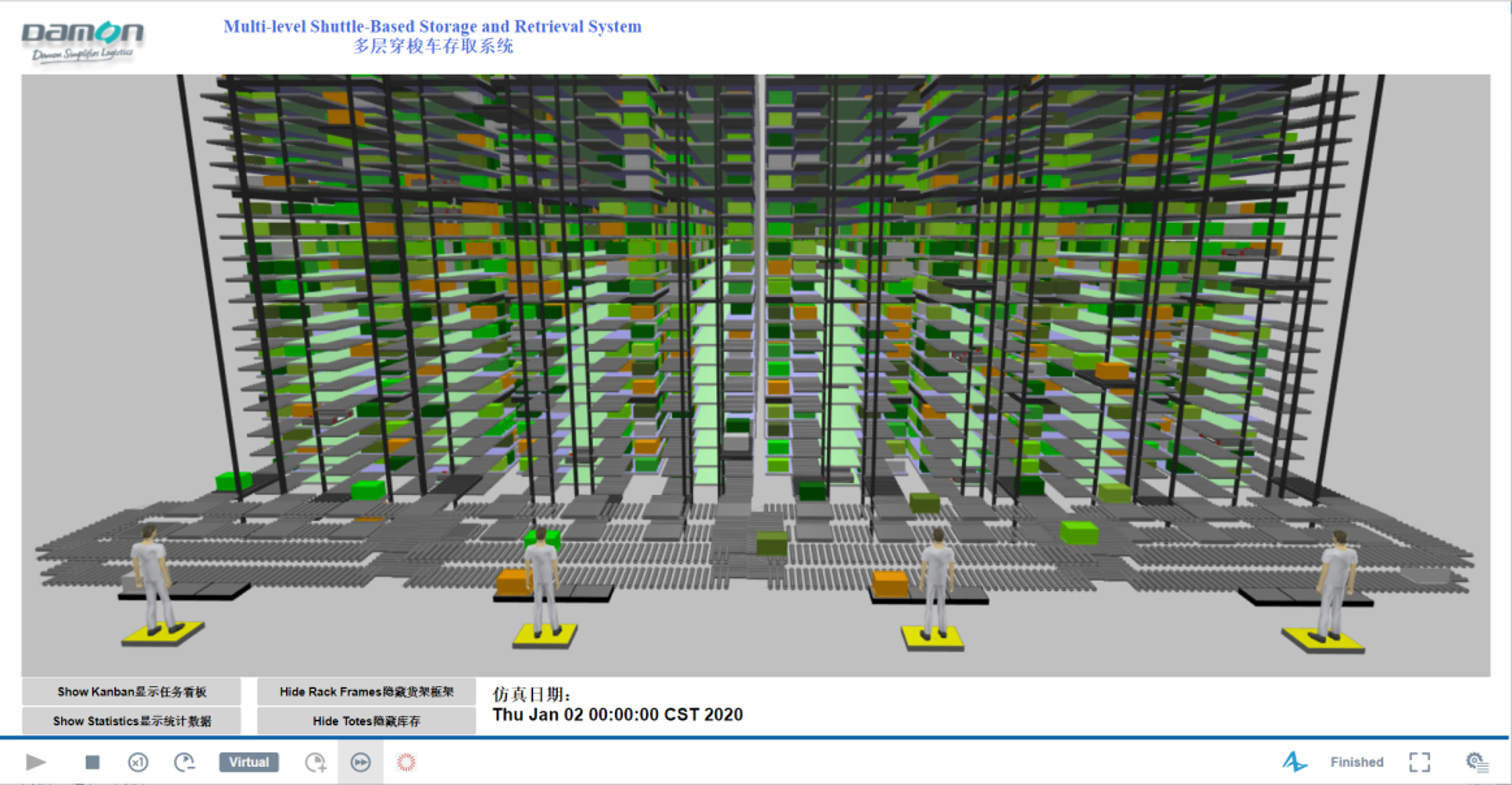

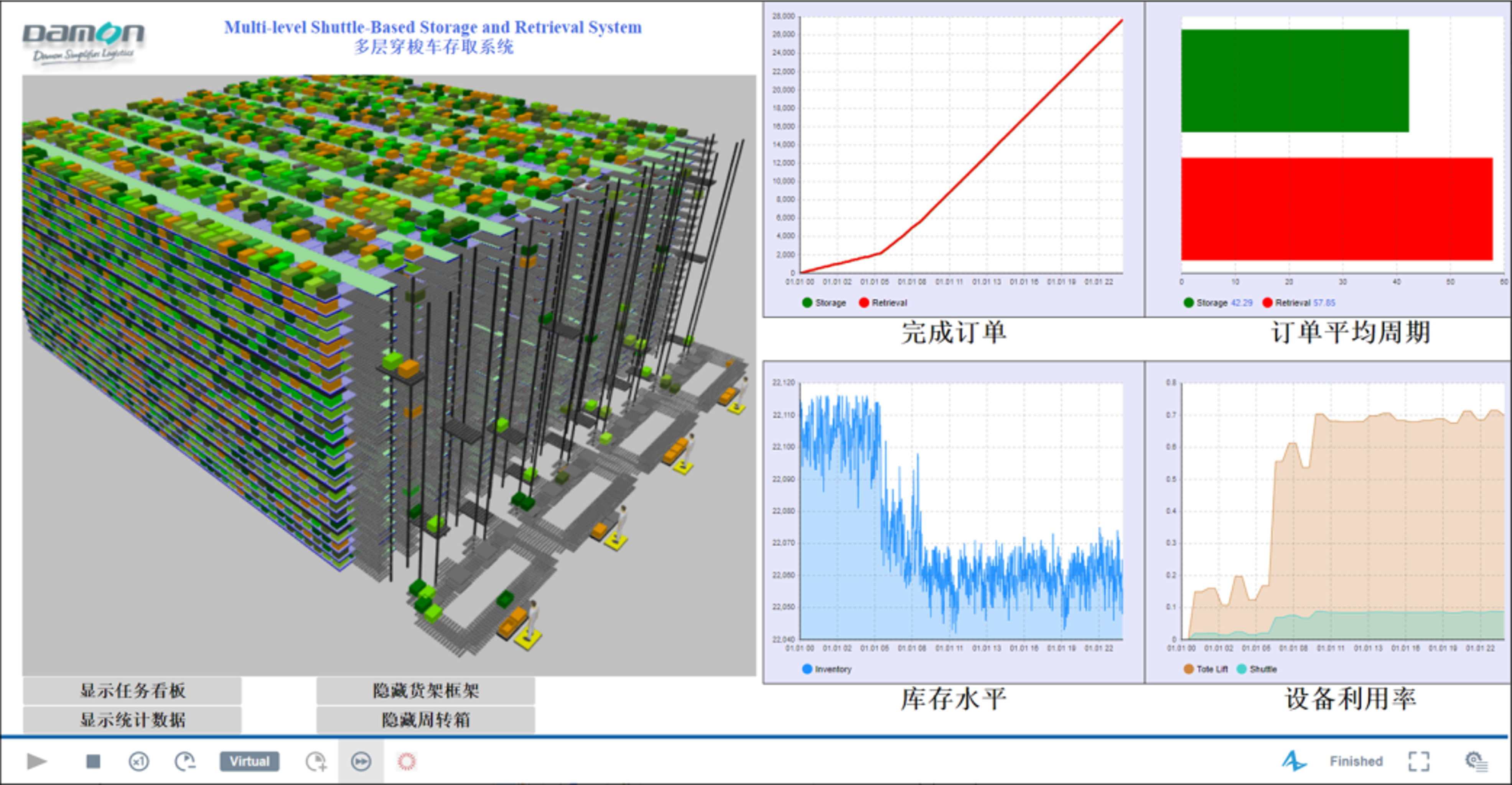

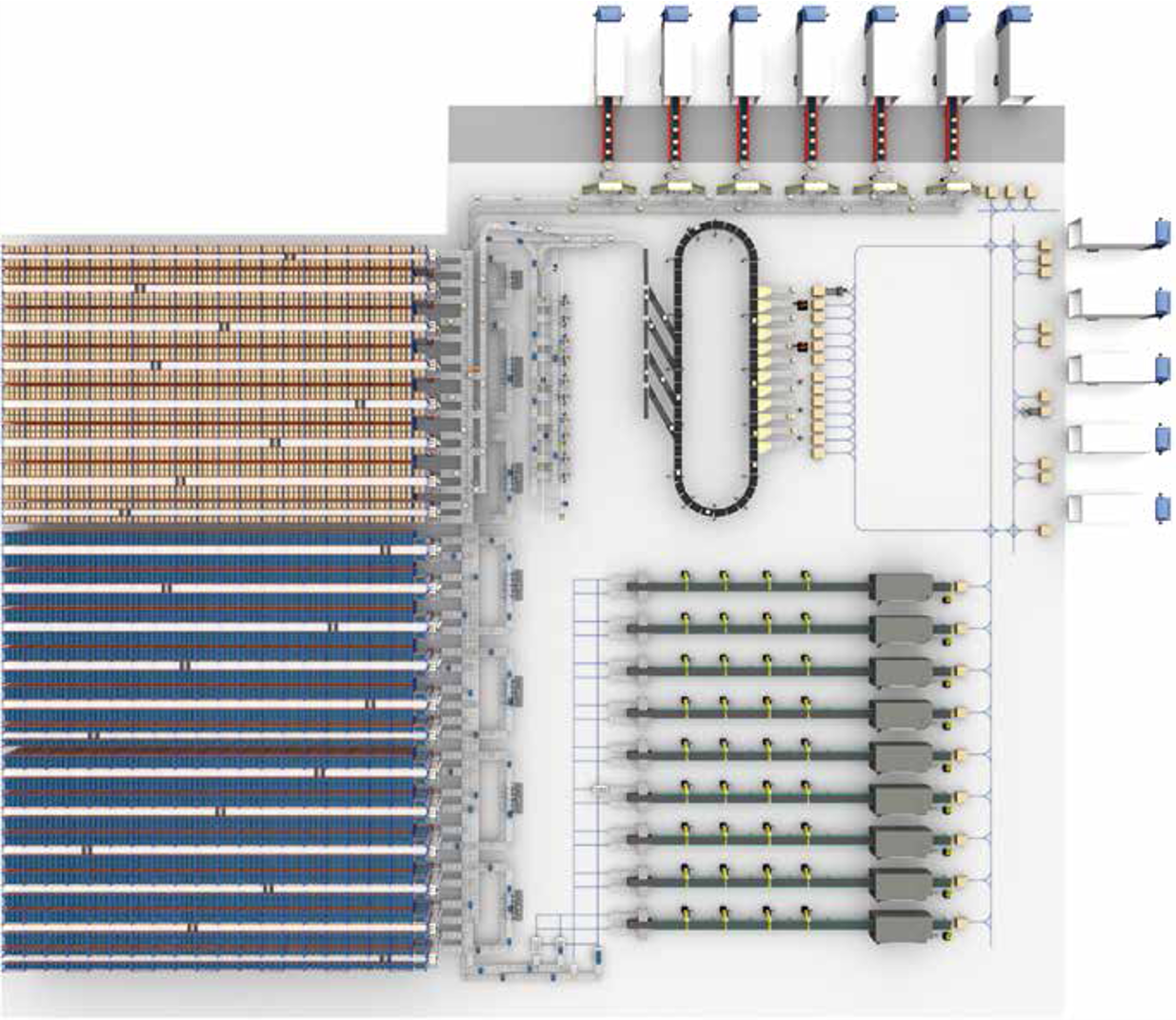

The Damon high-speed multi-shuttle system is mainly composed of intelligent carton shuttle, high-speed reciprocating lifter, layer changing lifter, intelligent equipment scheduling software and simulation system, WCS / WMS system and Phegda system. The core equipment is independently developed. After systematic and scientific long-term life pressure test, the stable and reliable operation of the equipment is ensured. The system has strong availability. Through the upstream WMS system, instructions are issued to the WCS system to complete the delivery and warehousing of orders. At the same time, it can also monitor the operation status of equipment and carry out remote preventive maintenance. The intelligent shuttles are backup to each other. If any one fails, the standby shuttle can be called for replacement to ensure the normal operation of the system.

The system can be widely used in high-density storage and rapid sorting of carton or box items in many industries such as e-commerce, medicine, tobacco, shoes and clothing, accessories, books, 3C, intelligent manufacturing, etc., to meet the needs of warehouse upgrading and diversified logistics throughput. At the same time, it is also suitable for effective connection with garment production line, so as to achieve the goal of lean production and management. In addition, the modular design of the equipment makes the system more flexible. Different numbers of shuttles and lifters can be flexibly configured according to the customer's business characteristics, so that the customer can have more choices between balancing cost and efficiency, find a suitable cost-effective system combination scheme and solve the business pain points.

The system can be widely used in high-density storage and rapid sorting of carton or box items in many industries such as e-commerce, medicine, tobacco, shoes and clothing, accessories, books, 3C, intelligent manufacturing, etc., to meet the needs of warehouse upgrading and diversified logistics throughput. At the same time, it is also suitable for effective connection with garment production line, so as to achieve the goal of lean production and management. In addition, the modular design of the equipment makes the system more flexible. Different numbers of shuttles and lifters can be flexibly configured according to the customer's business characteristics, so that the customer can have more choices between balancing cost and efficiency, find a suitable cost-effective system combination scheme and solve the business pain points.

Easy playing, supply chain combines three scenes of the garment industry

Damon multi-shuttle system has two functions of massive SKU dense storage and fast access, and supports double-depth storage flexible deployment, so that it has been well expanded in terms of goods-to-person picking and merging cache.

Massive dense access

Damon multi-shuttle system adopts three-dimensional racks, the shuttles walk on the rack rail , takes and puts the workbin, and is equipped with a double working station high-speed vertical conveyor that can handle 2 cartons of goods at the same time, so as to complete the handling of 25 meters high-level workbin, make full use of the upper storage space, improve the floor efficiency and save the cost. As the clothing products are relatively regular, the ability of the multi-shuttle system can be released.

Typical multi-shuttle technology focuses on the balance between single machine performance and equipment capacity. Combined with the functions of intelligent equipment scheduling, task allocation, scientific order management and warehouse location optimization, Damon multi-shuttle system can give full play to the advantages of two key equipment, intelligent shuttle and vertical reciprocating conveyor, and realize the dense storage of whole and bulk stacked SKUs. The system aisle has strong handling capacity of single and high access efficiency in the reservoir area, with a throughput of 2000 cartons/ hour, so as to realize rapid access in horizontal and vertical directions.

Quick broken casing picking

The surge of scattered orders in the garment industry makes the broken casing picking link a major difficulty in the garment logistics warehouse. More and more enterprises are beginning to consider choosing customized picking solutions. With the continuous expansion of the scale of garment enterprises and the increasing shortage of land, in order to complete a large number of sorting work in a relatively narrow space, "goods-to-person" sorting is an excellent solution. In recent years, the application of goods to people picking technology in garment logistics center is growing rapidly. The lightweight intelligent carton multi-layer shuttle system opens up a new application scenario for the "goods-to-person" picking solution, and successfully solves the problem of manual labor of workers in a monotonous and heavy working environment.

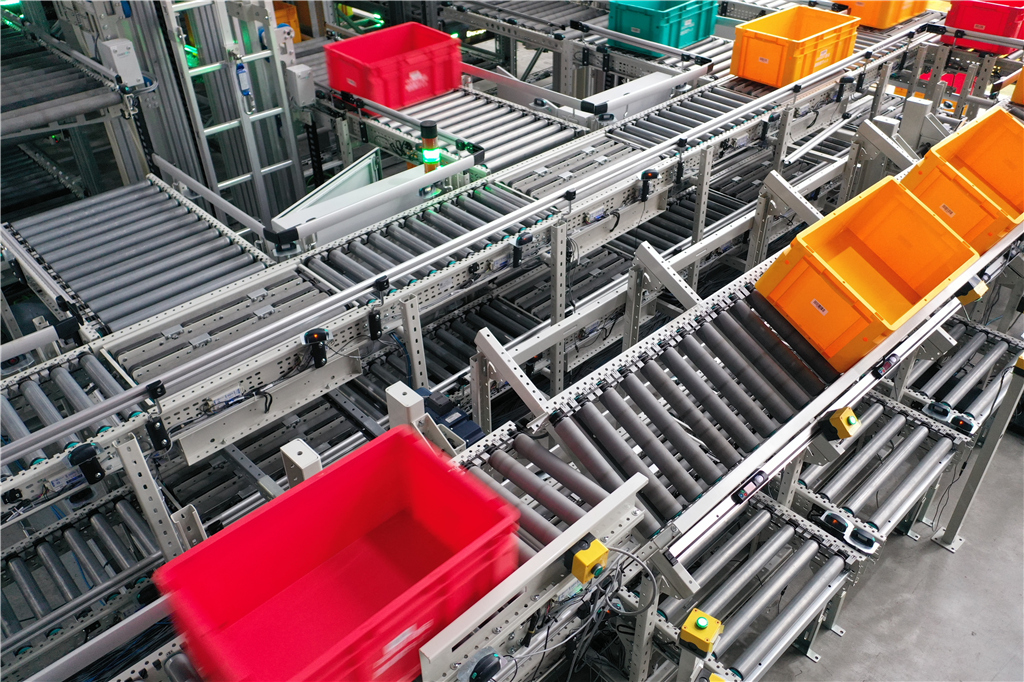

The R&D positioning of Damon multi-shuttle system is not only carton type centralized storage, but also focuses on the application in the "goods-to-person" picking solution. It is mainly applicable to the broken casing picking of clothing products with huge SKU, shallow storage depth and large picking surface. The system can be seamlessly connected with the star product i-G5 Modular Intelligent conveying platform and used together with Damon's goods-to-person sorting workstation to form a "access, conveying and picking" multi-shuttle system "goods-to-person" sorting solution, which not only greatly improves the sorting efficiency and accuracy, saves a lot of manpower, effectively reduces the labor intensity, but also greatly improves the efficiency of loading and cargo handling.

Among them, it is very important to design sufficient cache capacity of carton conveyor line to match the delivery capacity of multi aisle and the picking capacity of operators. The design of the picking workbench is ergonomic. All SKUs automatically transported to the workbench can be manually picked here, which reduces the walking distance and finding time of personnel, and improves the speed of manual picking.

In order to explore the automation of garment logistics, Vipshop's e-commerce B2C logistics center in Guangzhou has made a variety of attempts, including two sets of multi-layer shuttle "goods-to-person" picking system. For another example, in an intelligent factory in Huzhou, Damon adopts 8 shuttle, 4 lifters and 1 set of conveying and picking system for overall layout, and constructs a new centralized "goods-to-person" picking system, which realizes the functions of warehousing, picking, inventory counting and replenishment of containers of different specifications, and improves the efficiency of manual picking by 5-7 times compared with the original manual picking, Greatly reduce labor and corresponding management costs, can operate continuously for 7x24 hours, and ensure the efficient performance of orders.

Merging cache

The "life" of the garment industry lies in the inventory. Through the big data analysis of the historical warehousing and outgoing, Damon multi-shuttle system can judge the rationality of the inventory status in real time. The dynamic intelligent early warning greatly reduces the system error rate, realizes the synchronous temporary storage of large sales orders and small replenishment orders, and avoids the inventory shortage in the peak sales period.

In the clothing e-commerce distribution center, millions of SKUs are distributed in different picking areas. As a collection cache area, Damon multi-shuttle system combines all clothing goods in the order, and sends them to the packing table for delivery after the order is combined. When orders are delivered synchronously, all goods are scanned and sorted by sorting equipment outside the aisle to prevent cross color and code when clothes are delivered out of the warehouse. In the garment production line, the multi-shuttle system can also be used as a cache library to balance the upstream and downstream production links, strictly sort the material orders, and deliver them to the packaging line in time and quickly.

In the future, the powerful Damon multi-shuttle system will continue to help the major garment logistics centers to simplify, improve the overall operation efficiency of the warehouse and facilitate unified and efficient reservoir management. Damon Technology has always been committed to meeting the application needs of multi-scene and multi-functional compatibility in the footwear and clothing industry, creating highly suitable intelligent logistics system solutions for customers, enabling the garment supply chain and creating value for more industry leading customers.

Share to: