Apr 08,2024

Why is Damon i-G5? The Secret Behind “Intelligence, Beauty, Flexibility, Agile and Green” is Revealed!

Unconsciously, the i-G5 modular intelligent carton conveyor platform independently developed by Damon has been on the market for 7 years. As the mainstay of the transportation and sorting industry, Damon i-G5 has helped thousands of enterprises around the world improve the quality and efficiency of logistics centers with its "smart, soft and green" characteristics and mature technical support. In the service process of the whole life cycle of i-G5 products, the challenges from customers' problems are always emerging. In this regard, we have collated and selected some of the customers concerned about Damon i-G5 related issues, today to reveal for you one by one!

1)What are the advantages of Damon i-G5 in terms of product performance and stability?

Damon i-G5 conveying speed can reach up to 120m/min, and the e-commerce industry logistics center for Damon i-G5 conveying system performance parameters are very high, in some specific projects in some areas, i-G5 line body conveying speed can even reach 130m/min.

Taking the project of a world-renowned cross-border e-commerce platform in Japan as a typical example, under the normal operating conditions of the customer's logistics center, the i-G5 main line can load and carry goods weighing up to 45kg, maintain a high-speed operation of 90-120 meters per minute, and run continuously for 22 hours per day with high intensity. After more than 26,000 hours of successful operation, Damon i-G5 conveyor system is still operating efficiently, providing strong support and guarantee for the high-quality operation of customer's logistics center with good product stability and strong ultimate pressure resistance.

In addition, Damon generally carries out regular spot inspection and maintenance of the i-G5 transmission line at the project site and the rapid replacement of key components every 3 months, extending the mean time between failures of equipment and ensuring the high-quality operation of equipment and system. Typically, the mean time to repair (MTTR) for Damon i-G5 conveyors is less than 30 minutes.

2)What are the advantages of Damon i-G5 in terms of green energy conservation?

Green and environmental protection is one of the essential features of today's intelligent logistics technology products. Damon i-G5 series conveyors adopt a low noise mechanical structure design, and its internal motor energy efficiency level has reached the national IE3 standard. Through advanced photoelectric sensing technology and high-efficiency power transmission system, i-G5 can flexibly control and optimize the operating parameters in real time, adjust the operating state according to the arrival situation, and automatically enter the sleep mode when is idle, thereby reducing equipment energy consumption and energy waste.

The i-G5 roller conveyor is equipped with a digital energy-saving chip power roller, equipped with DC24V brushless DC motor, the rotor of this motor uses permanent magnet magnet steel, which can reduce secondary losses, compared to the belt conveyor driven by AC speed regulation motor, the power roller conveyor model can reduce power consumption by about 25%.

Therefore, during the system program planning, large-scale select of i-G5 power roller conveyor model, increase the proportion of this model, which can further reduce the energy consumption of customer logistics center’s daily operation, play the effect of energy saving and emission reduction, and enpower the perfect realization of global customer ESG sustainable development goals.

3)What are the advantages of Damon i-G5 in terms of product flexibility?

Damon i-G5 modular intelligent conveying platform can carry cartons, plastic boxes, shoes and clothing packages of fixed size, which are widely used in e-commerce, express delivery, shoes and clothing, retail, medicine, intelligent manufacturing and other industries.

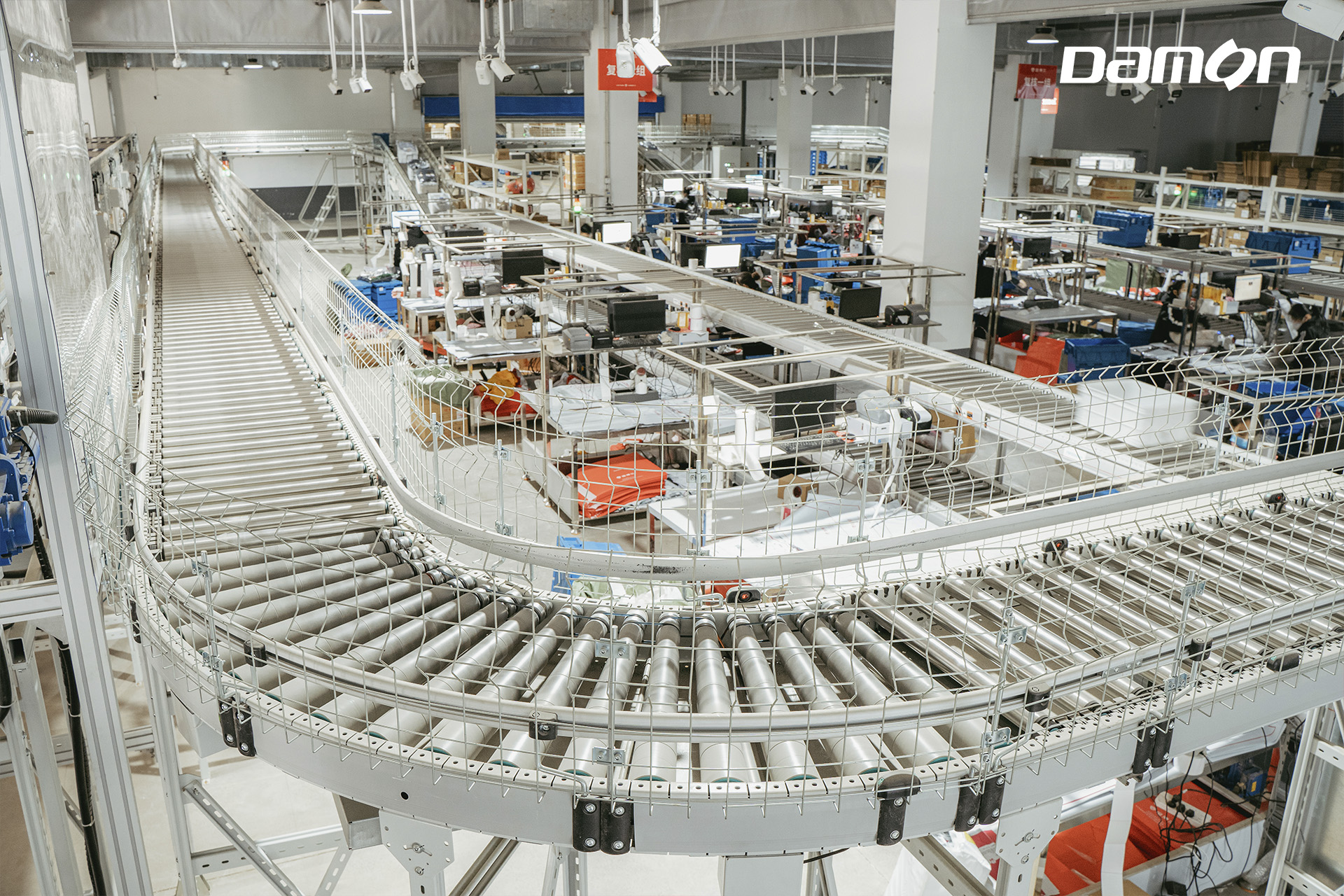

i-G5 series conveyor models mainly include three major categories: roller conveyor, belt conveyor, transfer, different sizes of the model will produce hundreds of millions of combinations. In addition, the i-G5 conveyor can be installed in the form of lifting, single, double and multi-layer ground installation, which allows to flexibly carry out system’s space deployment to meet the customized needs of customers.

Damon transports i-G5 series conveyors according to standardized modules, after arriving the site, standardized modules can be built into personalized systems by building blocks, thereby reducing the workload of installation and debugging and achieving system’s rapid delivery. For a typical i-G5 conveyor subsystem project, the delivery time of the whole machine is about 25-45 days, which is nearly double the delivery time compared to the previous generation.

2)What are the outstanding features of the Damon i-G5 in terms of appearance?

In today's Internet era, customers not only require the powerful functions of industrial products, but also pay more attention to the "appearance level" of conveyor, simple mechanical structure design, atmospheric industrial grade color matching, harmonious ergonomic layout, rich components selection, exquisite components installation technology... Every detail is extremely sophisticated, so that Damon i-G5 conveyor has become a work of art.

There are three types of i-G5 guardrail forms, each guardrail has its own characteristics, such as fast installation of plastic guardrail, beautiful appearance of aluminum alloy guardrail, plate guardrail is mostly installed in belt conveyor models, which are suitable for soft bags and flat parts and other special package transportation scenes. Users can choose guardrail with different profiles according to diversified application scenarios. At the same time, the color of supports, bracket, guardrail and side cover can be customized according to the specific needs of the user, so as to achieve both beauty and quality. In addition, the bottom of i-G5 conveyor can be equipped with two styles of cover and protective mesh to enhance the safety protection of goods and personnel under the high-altitude lifting layout.

Damon has been deeply engaged in the field of conveying and sorting for more than 20 years, and has been committed to going deep into the site and getting close to customers, so as to integrate and refine diversified needs, continuously increase innovation and research and development efforts, and achieve value co-creation with global customers with more high-quality products and advanced system solutions!

Share to: