Carton Warehouse Robot system solution

A new generation of tote robots developed by Damon for high-density and high-efficiency warehousing scenarios

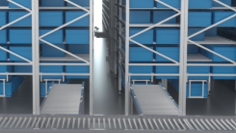

Carton Warehouse Robot system solution is a new generation of tote robots developed by Damon for high-density and high-efficiency warehousing scenarios. With its ultra-high operating speed and extremely narrow tote spacing, it significantly enhances storage efficiency and density. Combined with Damon's extensive product line, it forms various application solutions to meet the needs of diverse scenarios.

Carton Warehouse Robot + Conveyor System Solution

This solution integrates the Carton Warehouse Robot with Damon's traditionally strong conveyor systems, creating an automated, tripartite solution of "vertical storage, dynamic access, and high-speed distribution." The Carton Warehouse Robot utilize high-speed, three-dimensional access technology (with speeds of up to 4m/s) to rapidly retrieve totes from deep within the storage racks. They then seamlessly interface with the conveyor system for automatic sorting, achieving a system throughput of up to 500 cartons per hour per workstation.

Carton Warehouse Robot + AMR Solution

This solution utilizes the coordinated operation of multiple vehicle types, significantly overcoming the challenges of traditional systems, such as the inability to utilize vertical space and difficulties in improving efficiency. It enables the vertical and horizontal transfer of totes between different racks. AMR transport multi-level racks to the replenishment area, buffer zone, and picking stations based on operational needs. Supported by racks, cartons, and workstations, the system works in concert with Damon's AMR controller to efficiently execute tasks such as the inbound and outbound processes, stock replenishment, and inventory counting for both racks and totes.

Features

Higher Efficiency

The high-speed transport and lifting modules, combined with power configurations tailored for the cart-based and conveyor-based solutions, ensure optimal performance. Through STU automated sorting, targeted and best-selling inventory is consolidated into multi-tiered shuttle racks. This enables improved—or even controlled—rack hit rates and supports simultaneous picking and sorting.Higher Storage Capacity

Utilizing high-bay racks as the main storage area maximizes the use of vertical space, significantly increasing storage capacity. The compact design of the robots, along with customized grippers, enables transportation functionality even in tight spaces.Enhanced Flexibility

The system supports various types of underground-guided carriers—including single-layer, multi-layer, and overhead-mounted configurations—enabling mixed storage and picking of materials in small, medium, and large packaging sizes. It can be flexibly integrated with traditional conveyor systems or AMR (Autonomous Mobile Robot) products to form diverse solutions tailored to customers' varied needs.Reduced Equipment Investment

The product adopts a modular component design with a wide range of options, all rigorously tested for reliability exceeding 1.5 million cycles. The actuator features foolproof pick-and-place mechanisms for easy installation and shortened implementation time. Additionally, components support quick disassembly, and dedicated maintenance tools are designed for rapid replacement of entire units, significantly reducing equipment maintenance time.

-

Standard design

Standard design -

Intelligent control

Intelligent control -

Multiple protection

Multiple protection -

Flexible expansion

Flexible expansion

Model

STU Product Series

Carton Warehouse Robot + Conveyor System Solution

Carton Warehouse Robot + Conveyor System Solution

How Can We Help?

If you do have any question about our products and solutions, we are happy to communicate with you.

Contact us

Service Support

We provide you with the better advice and quick actions any time after purchasing our products.

Get help

By clicking on the button “I accept” or by further usage of this website you express consent with usage of cookies as well as you grant us the permission to collect and process personal data about your activity on this website.Such information are used to determine personalised content and display of the relevant advertisement on social networks and other websites. More information about personal data processing can be found on this link.Read More