Sep 18,2021

Focusing on the Cold Chain Track, Dasun Intelligent Appeared with the Logistics Solution of Cold Chain Intelligent Factory

From September 16th to 18th , 2021, the 13th Global Cold Chain Summit, co-sponsored by China Federation of Logistics and Purchasing and Global Cold Chain Alliance, was grandly held in Kempinski Hotel Suzhou. With the theme of "Double Cycle Pattern · Reshaping New Order", this summit focuses on the development trend of cold chain and related industries, invites government agencies, experts, scholars and enterprise executives to share the latest business cases, value concepts and innovative technologies, strengthen international industry exchanges, and jointly explore new opportunities and challenges of cold chain industry in the post epidemic era, help cold chain enterprises adapt to future market demand and realize leapfrog transformation.

Cold chain intelligent factory logistics solution expert

As a professional cold chain intelligent factory and intelligent logistics solution supplier in China, Dasun Intelligent, a wholly-owned holding subsidiary of Damon Technology, was invited to participate in the exhibition, and brought the special efficient intensive access and vertical lifting solutions for the three cold storages.

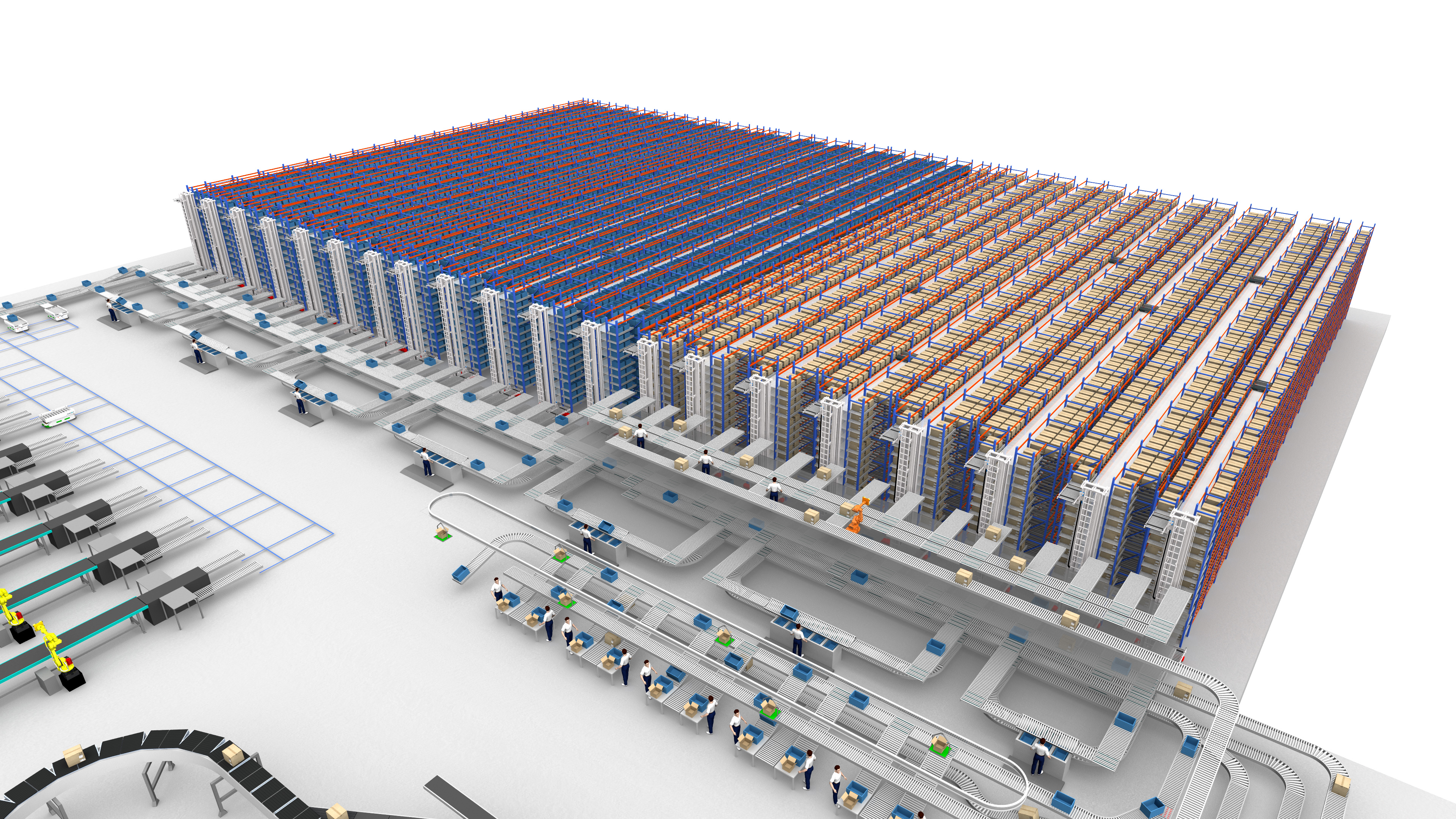

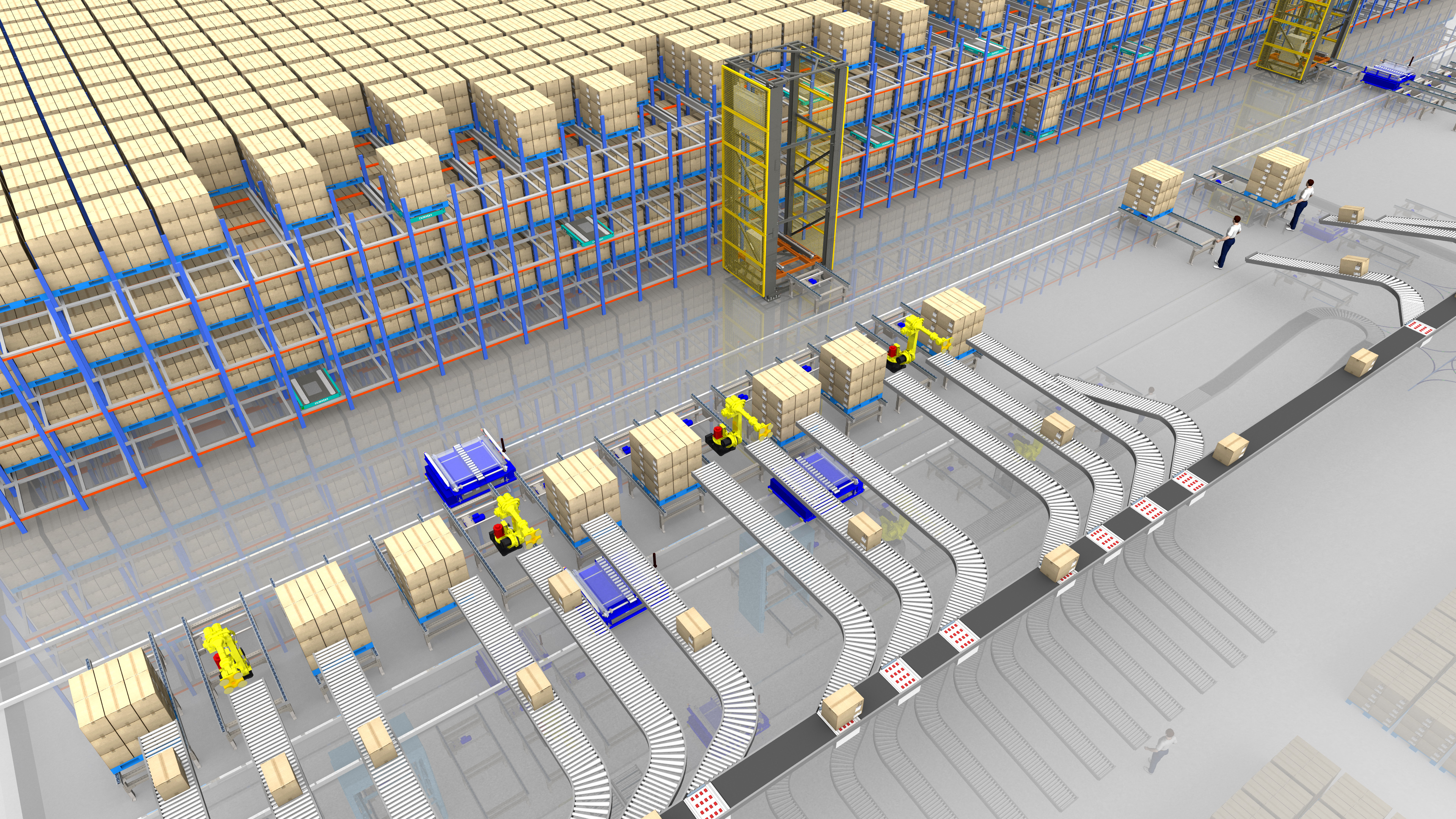

Starting from the production process of intelligent manufacturing, Dasun Intelligent adopts advanced technologies such as machine vision, artificial intelligence and big data analysis to provide system core equipment such as intelligent multi-layer shuttle, intelligent pallet shuttle, vertical lifter, stacker, conveying and sorting equipment, and cooperate with the independently developed MES, WMS, WCS, Phegda system and other intelligent production scheduling software. Starting from the arrival of raw materials, we customize a series of intelligent manufacturing whole plant logistics solutions for customers, such as automatic access, supply, picking, loading and unloading at working stations and cross-floor handling conveying of raw materials, semi-finished products, finished products and packaging materials.

Cold Storage Special Carton Type Multi-layer Shuttle Automatic Access Solution

Excellent adaptability to cold chain environment

1)High temperature difference hardware design: Adapt to --25℃~45℃ environment

2)48V contact supply line for power supply, safe and stable

3)7×24 hour continuous operation, guarantee order fulfillment capability

Excellent space utilization

1)Used for new warehouse, old warehouse transformation, production line side storage area, cache warehouse, etc

2)It is suitable for the transformation of various special-shaped spaces

Accurate and efficient

1)Compared with manual picking, the efficiency is improved by 5-7 times

2)Picking accurate rate>99.99%

Flexible scalability

1)Shuttle/aisle can be added temporarily, easily respond to big promotion and business growth

2)You can set storage allocation rules independently to deal with bussiness mode and need change calmly

Cold Storage Special Intelligent Pallet Four-way Shuttle Automatic Access Solution

Wide adaptability

1)High temperature difference hardware design: Adapt to --25℃~45℃ environment

2)Pallet,two way entry pallet, four way entry pallet and other pallets

3)Used for new warehouse, old warehouse transformation, production line side storage area, cache warehouse, etc

4)Widely used in e-commerce, supermarket, medicine, electronic industry

Excellent space utilization

1)Channel and pallet access channel are integrated, the storage capacity of goods can be improved up to 3 times higher

2)It is suitable for the transformation of various special-shaped spaces

3)Under the same warehouse volume, the number of storage can be increased by > 25%

Energy-saving and cost-reducing

1)The power consumption of in and out of one pallet is 0.13kwh, saving 74% of power

2)Investment cost can be reduced by > 20%

Flexible scalability

1)Shuttle/aisle can be added temporarily, easily respond to big promotion and business growth

2)The shuttle can four-way drive, multiple shuttles works in the same layer, single shuttle failure will just influence partial efficiency not the whole operation

3)Can design the number of deep storage flexibly according to the SKU situations

Pallet-Cage Trolley Vertical Lifting Solutions

Professional design without fear of cold

1)Operating temperature range:-10℃~40℃

2)Photoelectricity and detection equipment of low temperature environment are adopted, all line joints are sealed

3)Blackened parts are coated with anti-rust paint, prevent the impact of condensation water

4)Special lubricating oil, will not be sticky when the temperature drops

Energy-efficient

1)Lightweight design, low power drive,conveying efficiency up to 90 pallet / h

2)Equipped with energy-saving auxiliary system, up to 40% capacitor savings, reduce energy consumption and co2 emissions by 25%

Super adaptability

1)Support pallet, trolley and other logistic containers across-floor transportation, conveying height up to 40M

2)Conveying goods maximum size can be up to W2900×L2900×H2400mm

3)Maximum goods loading is 2000Kg/pallet

Flexible rapid deployment

1)Adopt module design, fast assembly and transportation, plug and play, with convenient maintenance

2)Both new and existing buildings can be deployed

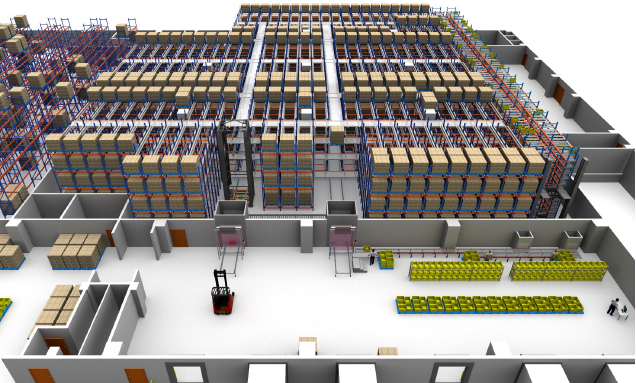

Application case of Wu Fang Zhai production cold storage

Wu fang zhai has a large e-commerce comprehensive logistics center and a three-dimensional warehouse for the storage of finished and semi-finished products. In order to complete the automatic docking of its production, e-commerce and store logistics, Dasun has planned four parts of multi-layer shuttle carton type storage area, pallet shuttle whole pallet storage area, transition handlingroom between cold storage and the outside and cargo-to-person picking area. Among them, the carton type multi-shuttle warehouse is used to access the frozen goods for broken case picking while the pallet four-way shuttle warehouse stores a large number of shipped frozen goods and replenishment products in the broken case area.

According to the characteristics of frozen products SKU, the storage is flexibly arranged, and the maximum storage access capacity can reach 2644 pallet+ 3344 cartons, so as to realize the high-density access of frozen products in the - 18~- 20 ℃ constant low temperature cold storage with an area of less than 2000 square meters, and greatly improve the space utilization and goods processing capacity. It can be used with 12 stackers, and the in and out of warehouse can reach 480 pallet/ h, greatly improving the access efficiency. It is not necessary to enter the freezing area manually to reduce the difficulty of manual operation.

It is worth mentioning that the cold storage adopts multiple small handlingrooms to replace the large hall. While making efficient use of the space, it greatly reduces the internal and external air exchange, energy conservation and consumption reduction, and reduces the risk of internal frosting. In addition, Dasun has also set up one pallet cargo-person working station and two carton type broken case picking working stations. The picking workstation is seamlessly connected with the carton type conveying line. The manual operation can easily complete the warehousing and warehousing of frozen products without walking, and can meet the picking requirements of 400 cartons / h at most.

With the consumption upgrading of China's new retail and the increasing demand for food cold chain, more and more deep and low temperature urban distribution centers need automatic logistics equipment to support. In order to make the products better adapt to different low-temperature environments, Damon Technology is building a low-temperature laboratory to study the low-temperature unmanned automatic access solution that can work in the cold environment of - 25 ℃. In the future, Damon will pay close attention to the domestic cold chain market, focus on large-scale cold chain projects, and continuously improve the degree of automation of products, so as to meet the operation needs of fine deep processing in the cold chain industry in the future.

About Dasun Intelligent

Zhejiang Dasun Intelligent Technology Co., LTD. is a wholly-owned holding subsidiary of Damon Technology. It mainly focuses on the production and logistics integrated system solutions of advanced intelligent manufacturing enterprises, involving many industries such as cold chain, food, fresh food, pharmaceutical, home, auto parts, shoes and clothing, textile, daily chemical and so on. Dasun has a professional design and manufacturing, scheme planning, system integration, project implementation and after-sales service team, which can give full play to the advantages of the integrated industrial chain from data analysis and system simulation to key equipment R & D, software development, installation and commissioning, training and operation, so as to build a high-quality modern intelligent manufacturing factory for enterprises.

Share to: